How to Install a Fiberglass Pool Shell (Step-by-Step)

Introduction

Welcome to “‘How to Install a Fiberglass Pool Shell (Step-by-Step)’,” your comprehensive resource for transforming your backyard with a beautiful and long-lasting fiberglass pool. Embarking on a DIY fiberglass pool installation is an exciting venture that not only enhances the aesthetic appeal of your home but also offers endless hours of enjoyment for you and your family.

How to Install a Fiberglass Pool Shell

Fiberglass pools are renowned for their durability, ease of maintenance, and quick installation process. Unlike traditional concrete pools, a fiberglass pool shell comes pre-formed and ready to install, making it an ideal choice for the DIY enthusiast. This guide is designed to walk you through the entire process of installing a fiberglass pool in your backyard, from the initial planning stages to the final touches.

Explore our

Fiberglass Pool Shells For Sale

and

Custom Pool Shells

to find the right size and shape before you begin.

By choosing to install your fiberglass pool, you’re not just adding a functional recreational area to your home; you’re also investing in a cost-effective solution that will increase the value of your property. Fiberglass pool benefits include a smooth, non-abrasive surface, reduced chemical usage, and minimal ongoing maintenance, ensuring that your pool remains a pristine oasis with minimal effort.

Learn more about our complete line of Fiberglass Pools.

This introduction will set the stage for a successful DIY fiberglass pool setup, covering the critical steps and considerations to ensure that your project goes smoothly. Whether you’re a seasoned DIYer or new to home improvement projects, this guide will provide you with all the information, tips, and tricks needed to confidently undertake your backyard pool installation.

Stay tuned as we dive into the world of fiberglass pools, offering you a detailed, step-by-step approach to creating your backyard paradise. With this ultimate DIY guide, you’ll be well on your way to enjoying the benefits of a fiberglass pool in no time.

Table of Contents

Introduction

- Overview of the benefits of fiberglass pools

- Brief explanation of the DIY installation process

Preparation

- Assessing your backyard for a fiberglass pool installation

- Checking zoning laws and obtaining permits

- Tools and equipment needed (e.g., 16 metric ton excavator, rubber track loader)

- Importance of having a clear plan (e.g., Latham dig sheet)

Site Preparation

- How to prepare the site for installation

- Checking the level of grade

- Removing obstacles (e.g., stumps) and disposing of them properly

- Setting corner stakes and marking the area for excavation

Excavation

- Step-by-step guide to excavating the site

- Using an excavator with a 28’ reach for difficult accesses

- Continually checking and adjusting the excavation depth and dimensions

- Tips for efficient and safe excavation

Preparing the Base

- How to prepare the base for the pool shell

- Importance of a solid and level base (using gravel and stone)

- Installing non-perforated pipes for drainage

- Screeding the area to ensure it’s perfectly level

Installing the Pool Shell

- Detailed steps for setting the pool shell in place

- Attaching the shell to the excavator with chains and a spreader bar

- Carefully positioning and lowering the shell into the excavated hole

- Checking for level and making adjustments as necessary

Plumbing and Backfilling

- Guide to installing plumbing and backfilling around the pool

- Starting plumbing with the heater and extending to skimmers and returns

- Proper backfill material and techniques for stability and drainage

- Ensuring the pool walls are supported during backfilling

Finishing Touches

- Final steps to complete the pool installation

- Installing additional features (e.g., lights, skimmers, equipment pads)

- Filling the pool with water and checking for leaks

- Landscaping and decking ideas to enhance your new pool area

Maintenance Tips

- Basic maintenance tips for your new fiberglass pool

- Regular cleaning and chemical balance

- Seasonal maintenance advice

- Protecting your pool during colder months with Inground Pool Winter Safety Covers

Conclusion

- Recap of the steps covered

- Encouragement for DIY enthusiasts and the satisfaction of completing the project

Efficient Installation of DIY Fiberglass Pool Shells

Embracing a DIY fiberglass pool installation offers a sense of accomplishment along with significant cost savings, particularly when using an inground fiberglass pool shell from trusted fiberglass swimming pool manufacturers. These DIY Fiberglass Pool Shells are celebrated for their easy installation, which can often be completed over a weekend by those with basic DIY skills. The simplicity of setting up a fiberglass pool shell is enhanced by its design, which typically includes pre-molded steps and seating areas. Before beginning, it’s crucial to select the appropriate backfill material, such as gravel, which supports the shell evenly and accommodates natural ground movements without shifting. This ensures the longevity and stability of your inground fiberglass pool, making the DIY route a practical option for many homeowners.

Creating a Personal Oasis with DIY Fiberglass Pools

A DIY fiberglass pool installation not only elevates your backyard but also turns it into a delightful retreat. The process of installing a fiberglass swimming pool involves meticulous planning and preparation but results in a durable and aesthetically pleasing addition to your home. The fiberglass pool shell is engineered for a straightforward fit, which simplifies the entire process from positioning the shell to the plumbing and final backfill. This hands-on project can be incredibly rewarding, as the final product brings endless hours of joy and relaxation. Furthermore, inground fiberglass pools require less maintenance than traditional concrete pools, making them an excellent choice for DIY enthusiasts looking for longevity and ease of care in their swimming pool solutions.

For the do-it-yourself enthusiast, installing a fiberglass pool shell presents an exciting challenge with a rewarding outcome—a personal oasis in your own backyard. The appeal of fiberglass pools lies in their ease of installation and minimal long-term maintenance. A standard DIY pool kit typically includes the pre-formed fiberglass pool shell, which has revolutionized inground pool installations, making it an accessible weekend project for many. Prior to installation, choosing the right backfill material is crucial to support the shell and prevent shifting. Innovative design makes these shells easy to install, with built-in tanning ledges and seating options to enhance your swimming experience. Once the shell is set in place, pool equipment like pumps and filters can be easily connected, thanks to user-friendly designs. Whether it’s a large inground fiberglass pool for the whole family or a smaller pool for intimate gatherings, DIY fiberglass pool shells offer endless possibilities to customize your outdoor space into a private retreat for relaxation and enjoyment.

Additional Detailed Guide to Installing a Fiberglass Pool Shell

The outline and step-by-step notes above give you a solid framework. In this expanded section, we’ll walk through each phase in more detail so you can better visualize the full project, understand why each step matters, and avoid common mistakes. Think of this as the “commentary track” that explains what’s happening and what to watch out for as you go.

1. Planning and Design Considerations

Before any dirt is moved, spend time planning the overall layout of your backyard. Stand in the space where you imagine the pool will be and consider:

Sun exposure: Pools are more enjoyable when they receive good sunlight during the day. Observe how the sun moves across your yard and position the shell where it will get the most use and warmth.

Privacy: Think about sightlines from neighbors’ windows or from the street. This is the time to plan for privacy fencing, hedges, or decorative screens.

Access for machinery: You will be using equipment such as a 16 metric ton excavator and a rubber track loader, so you need a clear access path into the yard. Sometimes this means temporarily removing a fence panel or gate.

Future features: Visualize where your pool equipment pad, deck, patio furniture, outdoor kitchen, or pergola might go. Leaving enough space now prevents frustrations later.

Taking photos and sketching a simple overhead layout can help you communicate clearly with any vendors or helpers. When you combine your plan with the Latham dig sheet and any engineered drawings, you get a clear roadmap that keeps the project organized.

2. Understanding Permits and Local Requirements

Every region has its own rules for pool installation. Before you begin:

Contact your local building department to ask about pool permits, inspections, and safety requirements.

Confirm setback requirements, which determine how close the pool can be to property lines, structures, and utilities.

Ask about barriers and fencing—many jurisdictions require specific fence heights, self-closing gates, and sometimes alarms on doors leading to the pool area.

Check utility locations by requesting a utility locate service. You must know where gas, electric, water, and sewer lines run before excavating.

Making sure your project is fully compliant from the start saves you from expensive corrections later and ensures your pool area is safe and legal.

3. Detailed Site Preparation

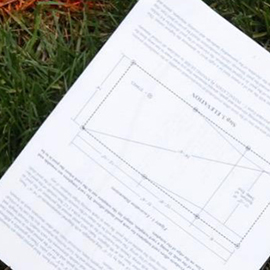

When you start to check level of grade to set height for pool shell, you’re really establishing the finished height of the pool in relation to the rest of your yard and any planned decking. This is a crucial step:

Use a laser level or transit to mark a consistent reference height on stakes around the site.

Consider drainage and slope away from the pool so water doesn’t pool around the shell or your home’s foundation.

Removing stumps and vegetation early, and having the tree vendor leave the stump at 3–4’ height, gives your equipment something to grab onto, making the removal much easier.

Once the topsoil is scraped off and the working area is clearly defined, you can begin setting corner stakes, confirming square for pool shell excavation, and running string lines. Taking the extra time now to double-check measurements and diagonals ensures that the pool will sit correctly in its final position and that your coping and decking will look even and professional.

4. Using Heavy Equipment Safely and Efficiently

Your equipment list—16 metric ton excavator with a 28’ reach and rubber track loader with a 68” bucket—is more than just a convenience; it’s what allows you to move large volumes of soil and heavy materials safely.

A few practical tips:

Operator experience matters. If you’re not comfortable running an excavator, consider hiring an experienced operator for the excavation and pool set days.

Plan your dump truck or dumpster locations so that excavated soil and stumps can be removed without blocking access to the hole.

Keep the job site organized. Designate areas for base stone, backfill material, and equipment pads so you’re not constantly moving materials around.

As you mark the hash marks for the excavator per dig sheet, you are essentially creating depth and contour guides. These marks keep the excavation accurate and match the specified shape and stepped depths on the dig sheet. Constantly updating these hash marks during excavation reduces the chance of over-digging, which would require additional stone and time.

5. Excavation: Going from Lawn to Pool Hole

When shell excavation begins, the process can feel dramatic. Lawn disappears and a large hole emerges quickly. Keep these points in mind:

Excavated dirt right into dump truck for removal is a clean and efficient method, preventing large soil piles from dominating your yard.

Getting down to grade requires patience—don’t rush the last few inches. Approach final grade slowly so you don’t remove too much material.

Stone in base with 2×4’s being screed for level is where precision really matters. A well-prepared base ensures the pool shell has continuous support.

The goal is a clean, flat, and level stone base that matches the dig sheet precisely. The screeding of the entire area creates a smooth and stable platform where the fiberglass shell can rest evenly, preventing future settling or stress points.

6. Handling and Setting the Fiberglass Pool Shell

Moving a fiberglass shell is one of the most exciting moments of the project. The combination of fastening chain to bucket of excavator, taping chain for extra precaution, and attaching a spreader bar distributes the load evenly:

Spreader bar on bucket ready to pick up pool shell ensures that lifting forces are balanced and that the shell does not twist or flex excessively.

Fastening straps to embedded chains on shell and fastening shackles should be done carefully, double-checking that everything is secure before lifting.

When picking up the pool shell and turning vertical for transport, move slowly and keep bystanders at a safe distance.

As you transport the pool vertically and place the pool in the excavated hole, communication between the operator and spotters on the ground is critical. Use clear hand signals or radios so everyone knows when the shell is moving, when to stop, and when adjustments are needed.

Once the shell is in place, checking bottom for voids ensures there is uniform contact between the shell and the stone base. Any hollow areas should be corrected immediately by slightly lifting that section of the shell and adding stone. After that, pool set in hole checking for level confirms that the shell is within acceptable tolerances—often not exceeding 1” over 40’.

7. Backfilling and Structural Support

The backfill material you choose plays a huge role in the long-term performance of the pool. As noted, stone for backfilling, do not use sand—clean, angular stone compacts well, drains effectively, and supports the shell without trapping water against it.

Key practices during backfilling:

Backfill all the way around with a machine when possible to keep the forces on the shell even.

Install the 8” non-perfed pipe for hydrostatic wellpoint while backfilling. This is your relief point for groundwater and a valuable long-term safeguard.

Use T-boards in place to keep walls straight, spanning across the pool to maintain correct width and prevent inward pressure on the walls as stone is added.

It’s common to backfill in lifts, adding a portion of stone, lightly compacting, and then adding water inside the pool shell to match the level of the backfill. This approach keeps pressure balanced between inside and outside the pool, protecting the structure.

8. Plumbing Layout and Best Practices

Your notes about pool plumbing with schedule 40 2” rigid pipe, propane tank and torch to heat pipes, and pipes heated to eliminate 90’s highlight a thoughtful hydraulic strategy. Gentle sweeps and minimal tight elbows improve water flow and reduce strain on the pump.

When planning your plumbing:

Keep plumbing ideally no more than 25’ from shell when possible, to maintain efficient circulation.

Clearly label suction and return lines, especially skimmer to pump, returns, and any vacuum or water feature lines.

The skimmer location on side wall to accept auto cover should be coordinated early so that cover tracks, skimmer height, and coping all work together.

Installing lights and plumbing to shell, including installing the coupling and 90 for light, typically happens while the pool is partially backfilled. Make sure all fittings are properly solvent-welded, and double-check manufacturer instructions for tightening and sealing light niches and conduits.

9. Equipment Pad and System Setup

Your equipment pads getting ready to be installed and leveled are the foundation for the operational side of the pool. Using AC pads or similar pre-formed slabs is a quick way to create a sturdy base.

On the pad, you will usually find:

Pool pump, sized correctly for the volume and hydraulic layout.

Filter, which might be cartridge, sand, or DE, selected based on your maintenance preference.

Heater, as noted in start of plumbing heater and heater plumbing cont, which extends your swimming season and keeps water comfortable.

Sanitizer system, such as a saltwater chlorine generator or tablet feeder, to maintain safe water chemistry.

Once the pool heater, filter, pump, and sanitizer are ready to be connected, take your time to align valves and unions so that future maintenance is straightforward. Keeping plumbing neat and accessible pays off every time you need to winterize, open the pool, or swap equipment.

10. Finishing Touches, Decking, and Landscaping

After shell ready for water usually the next day, the fun part begins—shaping the outdoor living space around your new pool. Finishing touches might include:

Coping and decking: Concrete, pavers, or natural stone can create a clean transition from pool edge to deck. Make sure expansion joints and drainage are properly planned.

Landscaping: Plantings, mulch beds, and low-voltage lighting soften the hard edges of the build and make evenings around the pool feel inviting.

Furnishings and shade: Loungers, umbrellas, pergolas, and side tables transform the area into a true retreat where family and friends will want to gather.

Once the pool is filled, check all connections for leaks, verify that skimmers and returns operate correctly, and balance the water chemistry. This is also a good time to walk around the pool at night with the lights on, making sure visibility and illumination are what you want.

11. Ongoing Care and Maintenance Tips

Your maintenance tips section touches on the basics, but it’s worth expanding a bit for long-term success:

Weekly tasks: Skim debris, empty skimmer and pump baskets, brush walls and steps, and test water for pH, chlorine, and alkalinity.

Monthly checks: Inspect filters, examine fittings for slow drips, and verify that the pump is primed and free of air leaks.

Seasonal prep: Before colder months, clean the pool thoroughly, balance the water, lower the water level if required by your cover system, and install Winter Safety Covers to protect both the pool and your family.

Because fiberglass surfaces are non-porous, they resist algae growth and staining better than many other pool types. This means that with modest effort and consistent water balance, your pool will keep its glossy look for many years.

12. Common Mistakes to Avoid

To help your project go smoothly, here are some frequent pitfalls and how to avoid them:

Rushing the base preparation: An uneven or poorly compacted base is one of the main causes of long-term issues. Always take extra time here.

Inadequate backfill material: Using sand or poor-quality fill can trap water and lead to shifting. Stick with clean, angular stone as noted.

Skipping inspections: If your local code requires inspections at specific stages, schedule them and get sign-off before moving on.

Overcomplicating plumbing: Too many unnecessary valves, tight 90° turns, or undersized pipe can create headaches. Keep layouts simple and efficient.

Learning from other installations and planning for these potential problems in advance will save time, money, and stress.

13. Example Project Timeline

While every project is different, here’s a general timeline for a typical DIY fiberglass pool shell installation:

Day 1–2: Permits finalized, layout marked, utilities located, stumps removed, grade checked.

Day 3–4: Excavation completed, soil removed, base stone installed and screeded.

Day 5: Pool shell delivered and set, initial backfill and water added.

Day 6–7: Plumbing, equipment pad setup, additional backfill, and electrical work by a licensed electrician.

Day 8–10: Coping, decking formwork, and concrete pour or paver installation.

Day 11–14: Final connections, water balance, site cleanup, and landscaping touches.

Some homeowners may stretch these steps over several weekends, while others may work with a small crew to complete things more quickly. The flexibility of a fiberglass shell makes it easy to adapt the timeline to your schedule and budget.

14. Final Thoughts and DIY Confidence Boost

Installing a fiberglass pool shell yourself is a big project, but it’s also a very achievable one when broken down into clear steps—planning, excavation, base preparation, shell placement, plumbing, backfilling, and finishing. The notes and phases you’ve seen above reflect real-world, practical experience: things like T-boards to maintain square, 8” well point non-perfed pipe, and heating pipes to eliminate 90’s all come from hands-on installations.

If you decide a DIY build isn’t the right fit, you can always choose our Full-Service Pool Installation option and let an experienced team handle the entire process for you.

By following the detailed process, respecting safety guidelines, and taking your time at each stage, you’ll end up with more than just a pool. You’ll have a backyard centerpiece you installed yourself, a place where memories are made, and a project you can look at every summer and say, “I built that.”