The Step-by-Step DIY Guide to Fiberglass Pool Shell Installation

Introduction

Welcome to “The Step-by-Step DIY Guide to Fiberglass Pool Shell Installation,” your comprehensive resource for transforming your backyard with a beautiful and long-lasting fiberglass pool. Embarking on a DIY fiberglass pool installation is an exciting venture that not only enhances the aesthetic appeal of your home but also offers endless hours of enjoyment for you and your family.

Welcome to “The Step-by-Step DIY Guide to Fiberglass Pool Shell Installation,” your comprehensive resource for transforming your backyard with a beautiful and long-lasting fiberglass pool. Embarking on a DIY fiberglass pool installation is an exciting venture that not only enhances the aesthetic appeal of your home but also offers endless hours of enjoyment for you and your family.

Fiberglass pools are renowned for their durability, ease of maintenance, and quick installation process. Unlike traditional concrete pools, a fiberglass pool shell comes pre-formed and ready to install, making it an ideal choice for the DIY enthusiast. This guide is designed to walk you through the entire process of installing a fiberglass pool in your backyard, from the initial planning stages to the final touches.

By choosing to install your fiberglass pool, you’re not just adding a functional recreational area to your home; you’re also investing in a cost-effective solution that will increase the value of your property. Fiberglass pool benefits include a smooth, non-abrasive surface, reduced chemical usage, and minimal ongoing maintenance, ensuring that your pool remains a pristine oasis with minimal effort.

This introduction will set the stage for a successful DIY fiberglass pool setup, covering the critical steps and considerations to ensure that your project goes smoothly. Whether you’re a seasoned DIYer or new to home improvement projects, this guide will provide you with all the information, tips, and tricks needed to confidently undertake your backyard pool installation.

Stay tuned as we dive into the world of fiberglass pools, offering you a detailed, step-by-step approach to creating your backyard paradise. With this ultimate DIY guide, you’ll be well on your way to enjoying the benefits of a fiberglass pool in no time.

Table of Contents

Introduction

- Overview of the benefits of fiberglass pools

- Brief explanation of the DIY installation process

Preparation

- Assessing your backyard for a fiberglass pool installation

- Checking zoning laws and obtaining permits

- Tools and equipment needed (e.g., 16 metric ton excavator, rubber track loader)

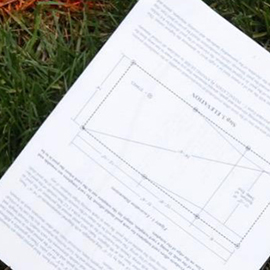

- Importance of having a clear plan (e.g., Latham dig sheet)

Site Preparation

- How to prepare the site for installation

- Checking the level of grade

- Removing obstacles (e.g., stumps) and disposing of them properly

- Setting corner stakes and marking the area for excavation

Excavation

- Step-by-step guide to excavating the site

- Using an excavator with a 28’ reach for difficult accesses

- Continually checking and adjusting the excavation depth and dimensions

- Tips for efficient and safe excavation

Preparing the Base

- How to prepare the base for the pool shell

- Importance of a solid and level base (using gravel and stone)

- Installing non-perforated pipes for drainage

- Screeding the area to ensure it’s perfectly level

Installing the Pool Shell

- Detailed steps for setting the pool shell in place

- Attaching the shell to the excavator with chains and a spreader bar

- Carefully positioning and lowering the shell into the excavated hole

- Checking for level and making adjustments as necessary

Plumbing and Backfilling

- Guide to installing plumbing and backfilling around the pool

- Starting plumbing with the heater and extending to skimmers and returns

- Proper backfill material and techniques for stability and drainage

- Ensuring the pool walls are supported during backfilling

Finishing Touches

- Final steps to complete the pool installation

- Installing additional features (e.g., lights, skimmers, equipment pads)

- Filling the pool with water and checking for leaks

- Landscaping and decking ideas to enhance your new pool area

Maintenance Tips

- Basic maintenance tips for your new fiberglass pool

- Regular cleaning and chemical balance

- Seasonal maintenance advice

Conclusion

- Recap of the steps covered

- Encouragement for DIY enthusiasts and the satisfaction of completing the project

For the do-it-yourself enthusiast, installing a fiberglass pool shell presents an exciting challenge with a rewarding outcome—a personal oasis in your own backyard. The appeal of fiberglass pools lies in their ease of installation and minimal long-term maintenance. A standard DIY pool kit typically includes the pre-formed fiberglass pool shell, which has revolutionized inground pool installations, making it an accessible weekend project for many. Prior to installation, choosing the right backfill material is crucial to support the shell and prevent shifting. Innovative design makes these shells easy to install, with built-in tanning ledges and seating options to enhance your swimming experience. Once the shell is set in place, pool equipment like pumps and filters can be easily connected, thanks to user-friendly designs. Whether it’s a large inground fiberglass pool for the whole family or a smaller pool for intimate gatherings, DIY fiberglass pool shells offer endless possibilities to customize your outdoor space into a private retreat for relaxation and enjoyment.